Description

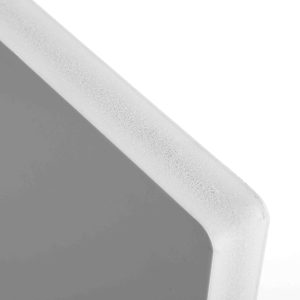

KINGSTAR PVC co-extruded foam sheet are using the co-extrusion process,making it like sandwich panel.The core of the panel is tight and evenly cell foam PVC and 2 sides skins are rigid non-foam PVC.This particular process makes the panel unique performance, provides a hard surface for both thin sheets and thick board. Making it become the good choice for the demanding outdoor, architectural, and industrial applications.

Product Range

| Product | KS-PVC Co-extruded Foam Sheet |

| Kind | PVC Foam Sheet |

| Size | 2440*1220mm; 3050*1560mm; 3050*2050mm |

| Thickness | 3-30mm |

| Density | Core:0.45-0.9g/cm³, Surface:1.2g/cm³ |

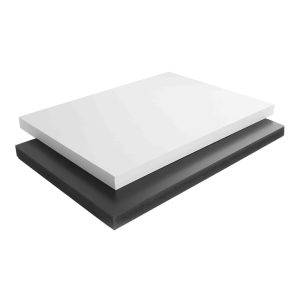

| Structure | Rigid PVC+Foam PVC+Rigid PVC |

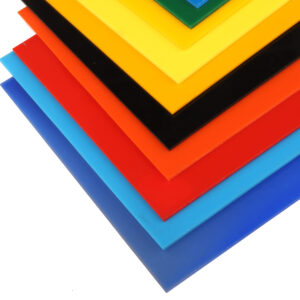

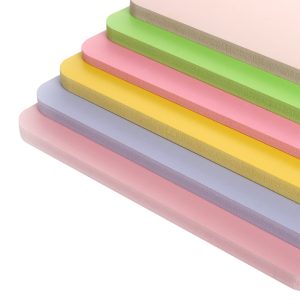

| Colour | White, Black, Grey, Blue, Red, Yellow, Green |

| Surface | High Glossy, Rigid |

| All dimensions specified are standard dimensions. Other sizes and colours can be customized. | |

Key Features

- Solid PVC surface skin

- High-gloss & non-porous finish

- Extreme impact resistance

- Superior weather and UV resistance

- Excellent chemical resistance

- Easy to clean and maintain

- Moisture resistant and impermeable

- Sound and vibration absorbent

Difference between Celuka and Co-extruded

| Feature | Co-extruded Foam Board | Celuka Foam Board |

| Manufacturing Process | Multi-layer extrusion (solid outer skin + foam core) | Controlled expansion (microcellular foam with smooth, hard outer surface) |

| Surface | Smooth and high glossy | Smooth with matte look |

| Strength | Strong impact resistance | Sturdy but with better toughness |

Outstanding Processing properties

Built for strength and long-term durability, PVC Co-extruded foam sheet is engineered to withstand demanding outdoor and structural applications, including large-format signage, cabinets, and furniture. Its enhanced load-bearing capacity and impact resistance support the following heavy-duty processing and assembly methods.

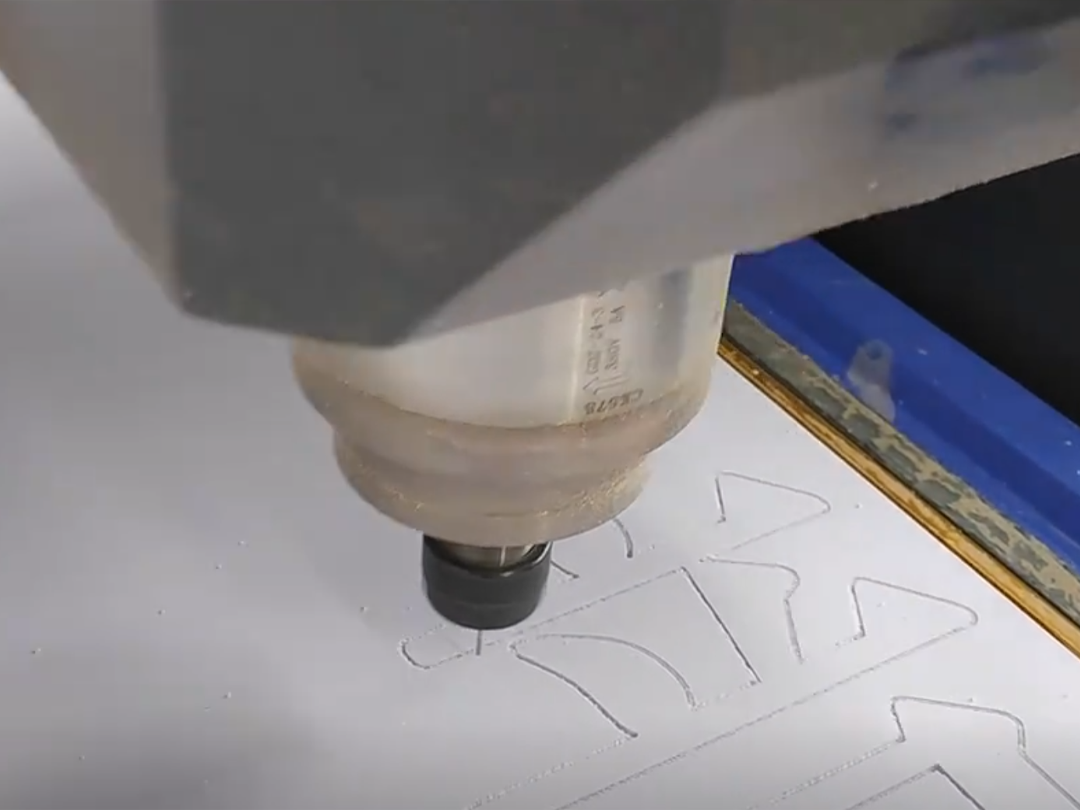

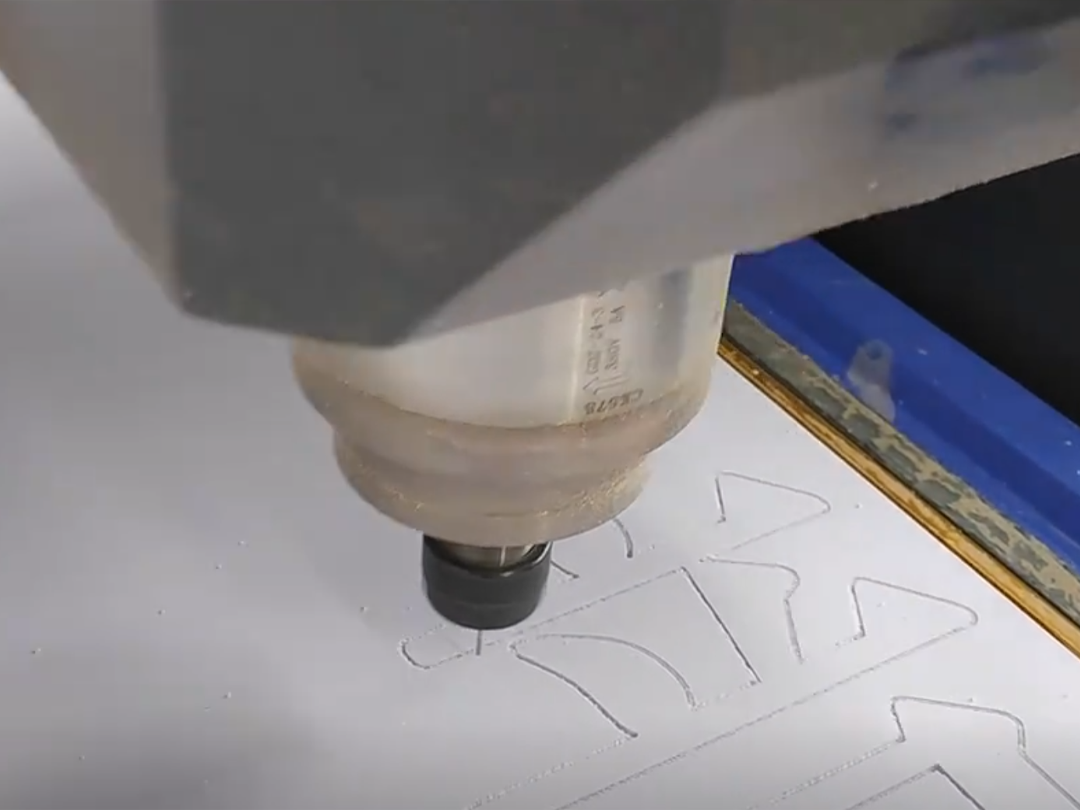

CNC Router

PVC Co-extruded foam sheet can be precisely cut, shaped, and profiled using CNC routers, making it ideal for producing large-format outdoor signs, durable furniture parts, and custom cabinet components.

Nailing

PVC Co-extruded foam sheet supports mechanical fixing with nails and staples, commonly used in backing panels, framing reinforcement, and quick assembly of structural furniture.

Screwing

Thanks to its enhanced structural strength, PVC Co-extruded foam sheet securely accommodates screws and bolts, providing reliable assembly for load-bearing furniture, cabinets, and outdoor installations.

Sawing

PVC Co-extruded foam sheet can be easily cut with standard panel saws or circular saws, allowing for efficient size customization and rough shaping in large-format applications.

Hinging

Durable hinges can be mounted directly onto PVC Co-extruded foam sheet using reinforced inserts or through-bolt methods, ensuring long-lasting performance for doors and access panels in cabinets and outdoor units.

Edge Banding and Sealing

The edges of PVC Co-extruded foam sheet can be finished with rigid banding or sealed to enhance durability and moisture resistance, essential for outdoor and high-traffic applications.

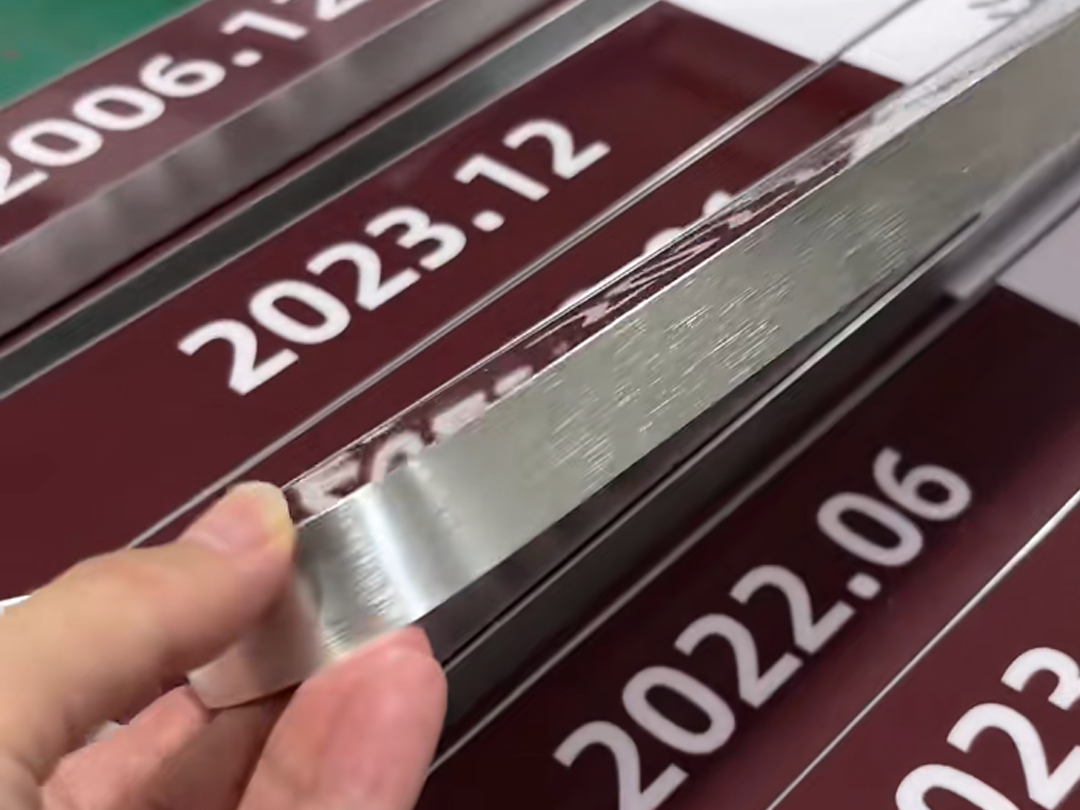

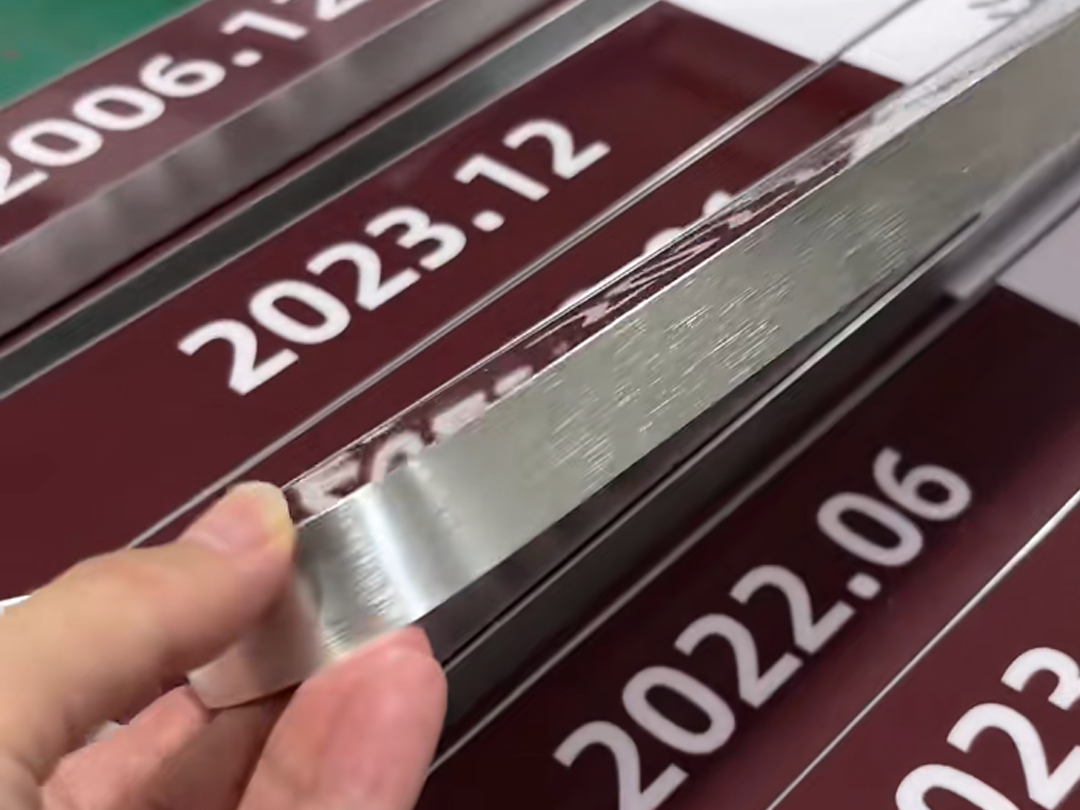

Engraving

Decorative patterns, logos, or textures can be precisely engraved onto PVC Co-extruded foam sheet, adding aesthetic details and non-slip surfaces for outdoor furniture or signage.

Drilling

Precision drilling and tapping can be performed on PVC Co-extruded foam sheet to create strong mechanical joints, suitable for assembling modular cabinets, shelving, and exhibition structures.

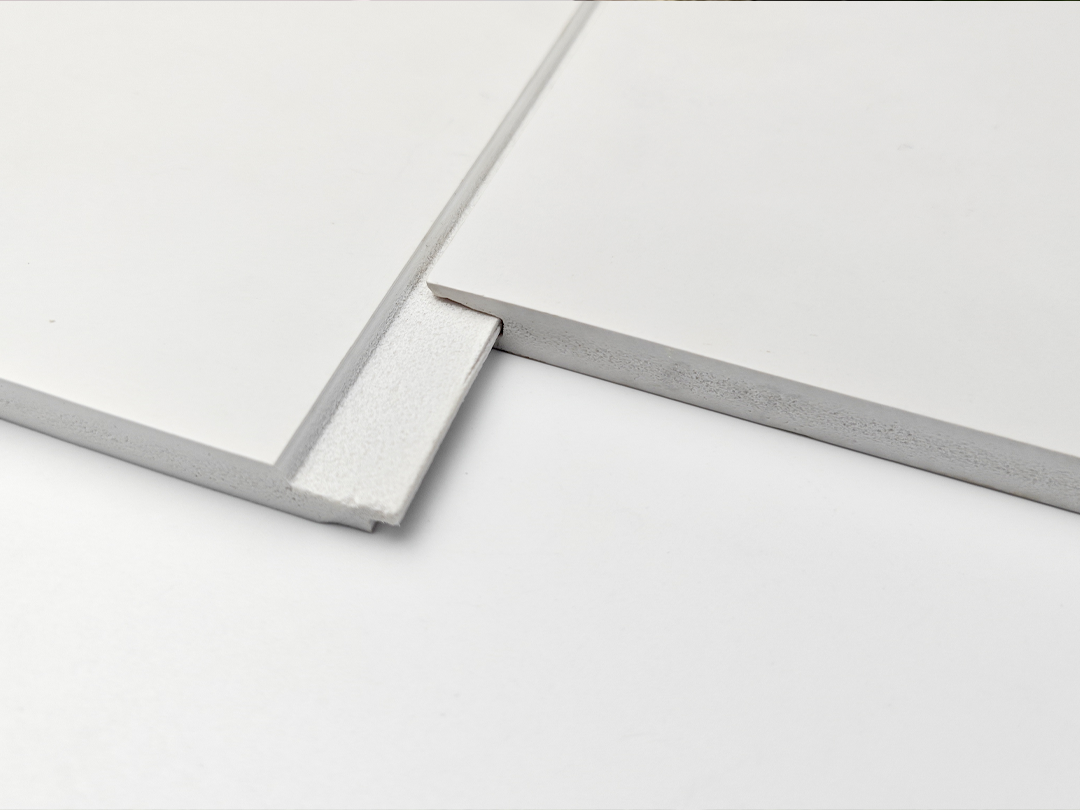

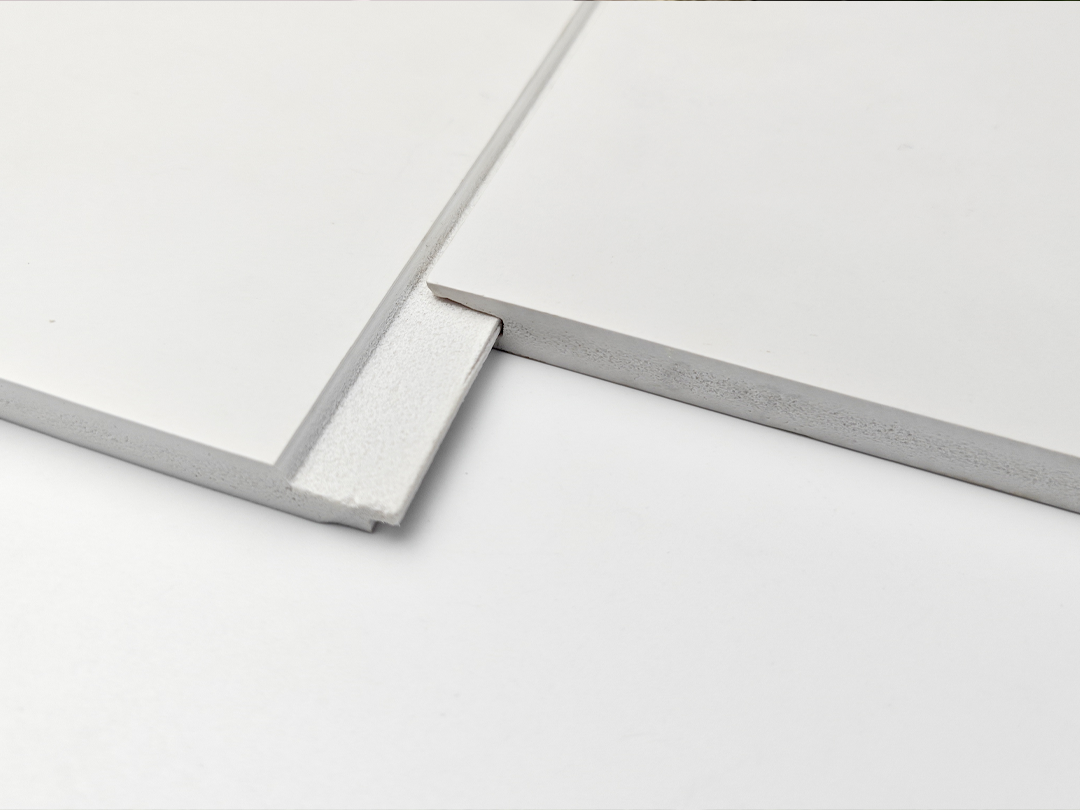

Tongue and Groove

Precise slots can be cut into PVC Co-extruded foam sheet to insert panels, conceal wiring, or seamlessly join two sheets edge-to-edge, creating a flat, seamless surface for high-end displays and furniture.

CNC Router

PVC Co-extruded foam sheet can be precisely cut, shaped, and profiled using CNC routers, making it ideal for producing large-format outdoor signs, durable furniture parts, and custom cabinet components.

Nailing

PVC Co-extruded foam sheet supports mechanical fixing with nails and staples, commonly used in backing panels, framing reinforcement, and quick assembly of structural furniture.

Screwing

Thanks to its enhanced structural strength, PVC Co-extruded foam sheet securely accommodates screws and bolts, providing reliable assembly for load-bearing furniture, cabinets, and outdoor installations.

Sawing

PVC Co-extruded foam sheet can be easily cut with standard panel saws or circular saws, allowing for efficient size customization and rough shaping in large-format applications.

Hinging

Durable hinges can be mounted directly onto PVC Co-extruded foam sheet using reinforced inserts or through-bolt methods, ensuring long-lasting performance for doors and access panels in cabinets and outdoor units.

Edge Banding and Sealing

The edges of PVC Co-extruded foam sheet can be finished with rigid banding or sealed to enhance durability and moisture resistance, essential for outdoor and high-traffic applications.

Engraving

Decorative patterns, logos, or textures can be precisely engraved onto PVC Co-extruded foam sheet, adding aesthetic details and non-slip surfaces for outdoor furniture or signage.

Drilling

Precision drilling and tapping can be performed on PVC Co-extruded foam sheet to create strong mechanical joints, suitable for assembling modular cabinets, shelving, and exhibition structures.

Tongue and Groove

Precise slots can be cut into PVC Co-extruded foam sheet to insert panels, conceal wiring, or seamlessly join two sheets edge-to-edge, creating a flat, seamless surface for high-end displays and furniture.